- Home

- Steel Maintenance

- JOTUN EPOXY HR

JOTUN EPOXY HR

A heat-resistant epoxy coating.

"*" indicates required fields

Jotun Epoxy HR is a two component polyamine cured phenolic/novolac epoxy coating.

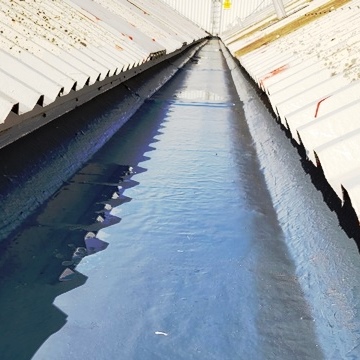

Jotun Epoxy HR is a high-performance, heat-resistant coating that delivers long-term protection in some of the most demanding temperature conditions. It withstands continuous exposure to temperatures up to 205 °C (401 °F) and performs effectively even at cryogenic temperatures as low as -196 °C (-321 °F). This wide operating range makes it a versatile solution for both insulated and non-insulated surfaces across a broad spectrum of industrial applications.

Engineers formulated Epoxy HR with advanced epoxy technology to ensure excellent water resistance and superior corrosion protection, even under harsh thermal cycling. It actively resists corrosion under insulation (CUI), which extends asset lifetimes, reduces unplanned maintenance, and helps facilities avoid costly shutdowns. As a result, operators choose Epoxy HR for critical environments where performance and reliability matter most.

Applicators benefit from Epoxy HR’s unique adaptability during maintenance operations. They can apply it directly onto hot substrates up to 150 °C without shutting down the system. It also adheres well to surfaces prepared to St2 standard (hand or power tool cleaning), making it a practical solution for urgent repairs or limited-access areas. This level of flexibility minimizes downtime and enhances application efficiency during turnarounds and site maintenance.

With over two decades of successful global use, Jotun Epoxy HR continues to prove its value as a trusted, durable, and efficient protective coating for extreme temperature service.

Key features

Heat resistant up to 205 °C continuous

Suitable for maintenance

Can be applied on hot substrates up to 150 °C

Reduced risk of CUI

For both insulated and non-insulated surfaces

Accepts St2 surface preparation

Certificates and Approvals

Tested in accordance to ISO 19277:2018

For more detailed and specific information about the standards, certificates and other documentation please see TDS.